Driven by data

100% adherence to specifications, delivering standardised results.

100% adherence to specifications, delivering standardised results.

Computer-vision, and advanced machine algorithm-based model with 360 degree rotation for complete surface check.

24 X 7 sorting with limited manpower increases yield.

Free of human-bias for accurate defect detection.

Reduces sorting cost by upto 90%

IoT enabled for real-time access to a rich set of data insights.

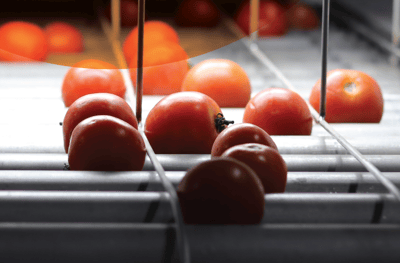

Intello Sort has over a dozen cameras that capture images from all angles. Each piece continuously rotates, scanning the entire surface of the fresh produce in seconds to weed out defective pieces.

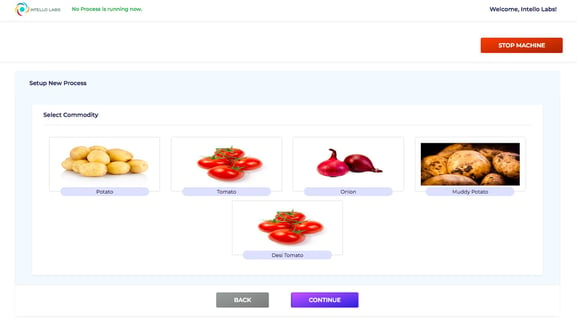

Through the user interface, you can configure Intello Sort to your quality parameter requirements. For one lot, sort potatoes based on size and defects. For another, sort them for color and decay.

With an easy-to-use and intuitive interface, you can start, pause, or alter parameters. Intello Sort, available in multiple formats, ensures maximum quality and safety. Without sacrificing sorting performance, it offers high yield.